Entry level brushless motor from Solink. The latest batch (May 2025) have the updated controller that increases torque 10-15% with the same RPM, enabling them to drive heavier loads more efficiently. In addition they have enhanced start-up performance, ensuring quicker response and overall a greater reliability during usage.

The external shell is CNC machined from aluminium. Uses a D Type pinion gear with a hardness rating of HRC35-38.

These motors have great heat efficiency, reliability and performance from either 7.4v or 11.1v. According to Solink you can use AB and Precock, and state their motors are fully compatible with all ETU's.

Solinks Motor FAQ

https://docs.google.com/document/d/1lkZ2AoD117quTZbo2PIHeNTvgCYvAkw4/

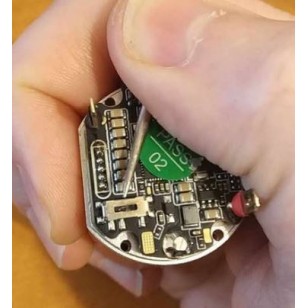

Speed Controller Tip

Whilst the LITE edition doesn't have an external speed (20% reduction) switch, you can access this by removing the 4 screws on end cap and using a pin switch the selector (see photo).

Motor Grip Modification:

I'll list up ones here when I start getting reports in but assume anything that isn't "standard" you'll need to modifiy the motor grip plate.

IMPORTANT

1. Do not power the motor with the cables reversed. Always check this.

2. Solink state that this is the most ETU compatible motor on the market and can be used with AB should you need to, no reported issues.

3. As with all motors if you get a gearbox lock-up, don't keep your finger on the trigger trigger. Use common sense.

4. If changing the pinion yourself do not force it on, do not whack with a hammer! Too much force will damage the rear bearing or controller. There's some good guides on YT on how to remove pinion gears on brushless motors.

-308x308.jpg)

-308x308.jpg)

-308x308.jpg)